Full Automatic Constant Pressure Variable Frequency Water Supply Equipment is a new generation of hi...

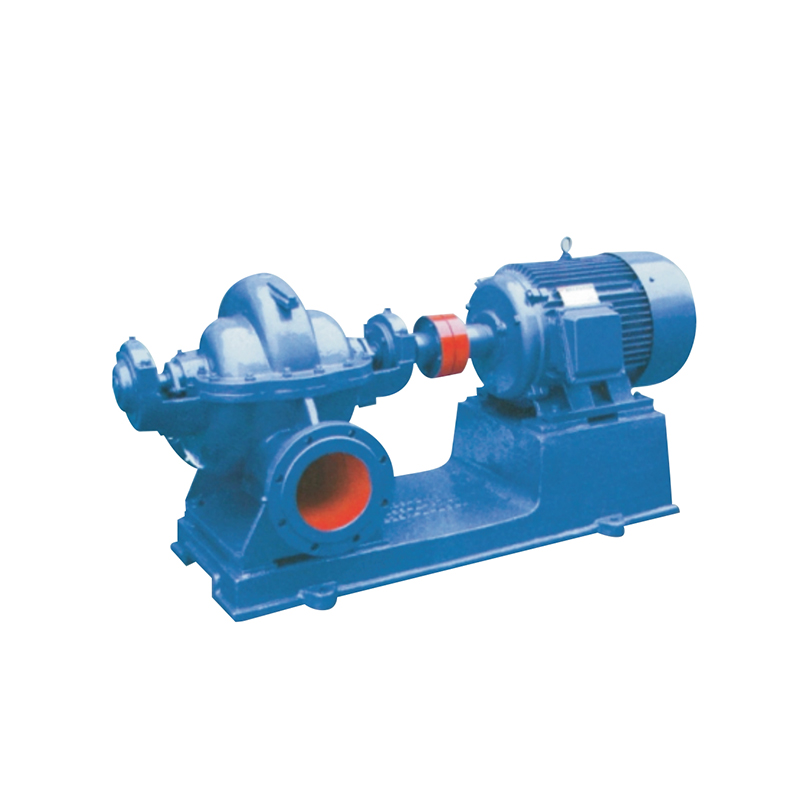

See DetailsDouble Suction Centrifugal Pumps: Transforming Industrial Fluid Dynamics with Enhanced Capacity and Reliability

Industry News-In the evolving landscape of industrial fluid handling, the Double Suction Centrifugal Pump is gaining significant traction as a powerhouse solution for high-capacity applications requiring both efficiency and stability. Recognized for its unique design and robust performance, this pump type is increasingly favored across sectors such as water supply, power generation, petrochemical, and large-scale HVAC systems.

What Sets Double Suction Centrifugal Pumps Apart?

The defining feature of the double suction centrifugal pump is its impeller design, which draws fluid into the pump casing symmetrically from both sides. This configuration balances hydraulic forces and reduces axial thrust on the pump shaft, to smoother operation and less mechanical stress.

This symmetrical suction design allows the pump to handle larger flow rates than conventional single suction centrifugal pumps of comparable size. It also enhances volumetric efficiency, making double suction pumps ideal for applications requiring high flow and moderate pressure conditions.

Industrial Advantages Driving Adoption

Industries worldwide are adopting double suction centrifugal pumps due to their ability to efficiently manage large volumes of liquid with reduced maintenance demands. Key advantages include:

High Flow Capacity: The double suction design significantly increases the pump’s flow capacity, making it a choice for municipal water treatment plants, flood control systems, and irrigation networks.

Reduced Shaft Load: Balanced hydraulic forces mean less wear on bearings and seals, which extends the pump’s operational lifespan and decreases maintenance frequency.

Energy Efficiency: Enhanced hydraulic efficiency energy consumption, aligning with global initiatives to reduce industrial carbon footprints and operational costs.

Versatile Installation: These pumps can be configured as horizontal or vertical units, depending on spatial and process requirements, offering flexibility in plant design.

Technological Progress Elevating Performance

Manufacturers are continuously innovating to improve the performance of double suction centrifugal pumps. Advances in Computational Fluid Dynamics (CFD) modeling have optimized impeller geometry, reducing turbulence and cavitation risks.

Modern materials, such as high-grade stainless steel and engineered composites, are being used to withstand corrosive and abrasive fluids, expanding the pump’s applicability to challenging environments like chemical processing and mining operations.

Automation and IoT integration are also on the rise, with sensors monitoring vibration, temperature, and flow parameters in real time. These digital enhancements facilitate predictive maintenance and remote operation, significantly reducing unexpected downtimes.

Market Trends and Global Demand

The global demand for double suction centrifugal pumps is on an upward trajectory, supported by rapid urbanization, infrastructure development, and industrial expansion. Water utilities investing in pipeline upgrades and wastewater management systems are major buyers of these pumps.

In power plants, where cooling systems require reliable, high-volume fluid circulation, double suction pumps ensure consistent performance even under fluctuating loads. The petrochemical industry, facing stringent safety and environmental standards, relies on these pumps for their durability and leak-proof designs.

Emerging markets in Asia-Pacific and Latin America are witnessing increased adoption, driven by large-scale infrastructure projects and government incentives aimed at improving energy efficiency and water resource management.

Case Examples Demonstrating Impact

Urban Water Supply: A metropolitan city replaced aging single suction pumps with double suction centrifugal pumps in its main water distribution network. The upgrade doubled the flow capacity without increasing energy consumption, significantly improving water availability during peak demand.

Power Generation: A thermal power plant integrated double suction pumps in its cooling system, achieving more stable operations and reducing maintenance costs by 30%. The pumps’ balanced design minimized vibration and extended equipment lifespan.

Chemical Industry: A chemical manufacturing facility handling corrosive liquids adopted double suction pumps with corrosion-resistant liners, ensuring safe and uninterrupted operations. Real-time monitoring enabled by IoT devices reduced downtime and improved process control.

Challenges and Considerations

While double suction centrifugal pumps offer many benefits, their initial cost is generally higher than simpler pump types due to more complex construction and precision engineering. Proper selection and sizing are critical to avoid performance issues such as cavitation or flow imbalance.

浙公网安备33032402001888号

浙公网安备33032402001888号