Continuously absorb and introduce excellent technologies based on actual conditions.

- Water Supply Equipments

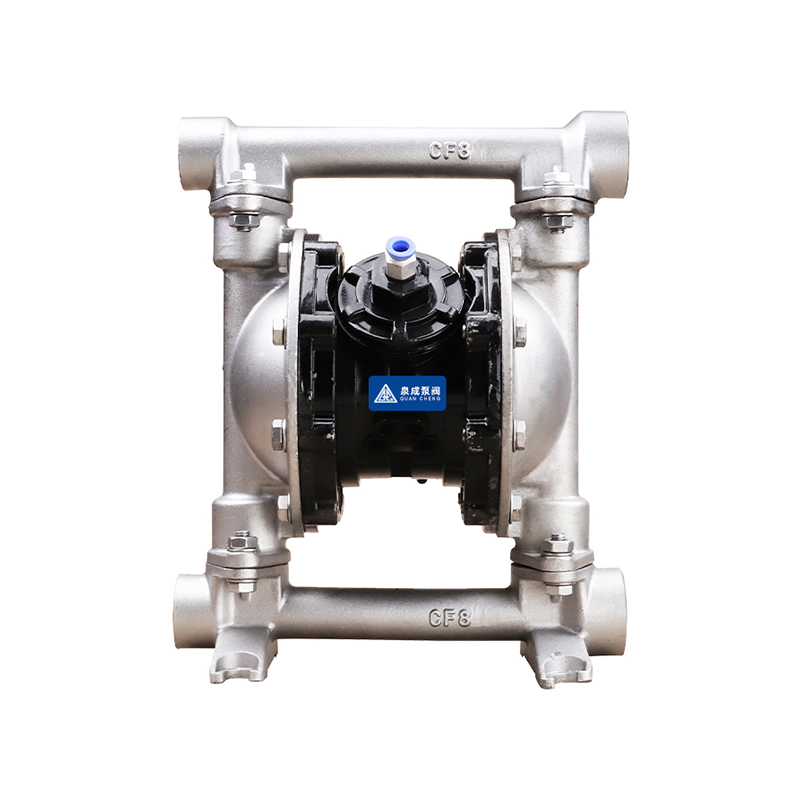

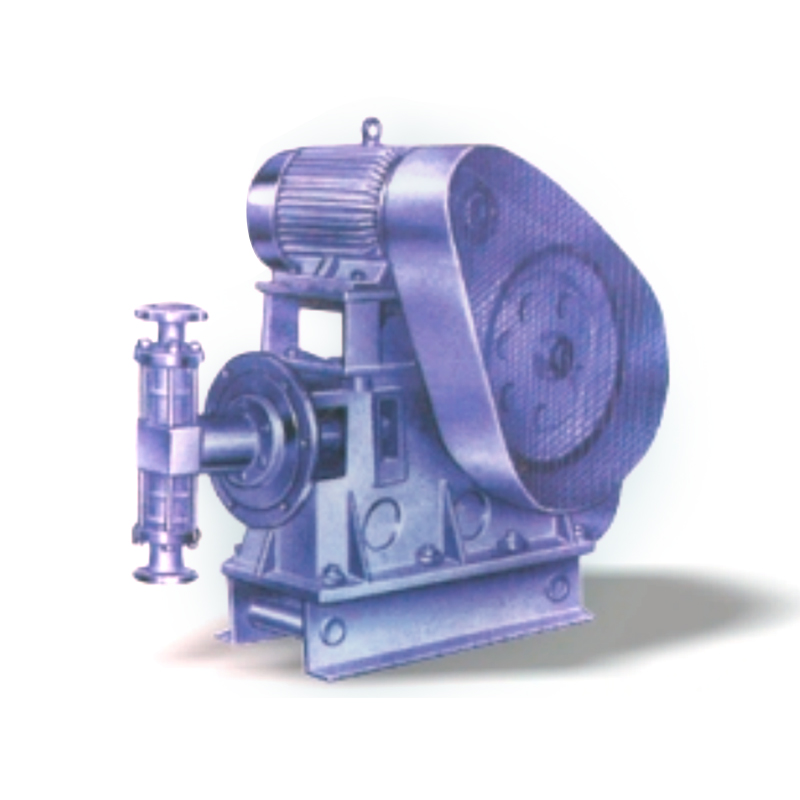

- Diaphragm Pumps

- Magnetic Drive Pumps

- Pipeline Pumps

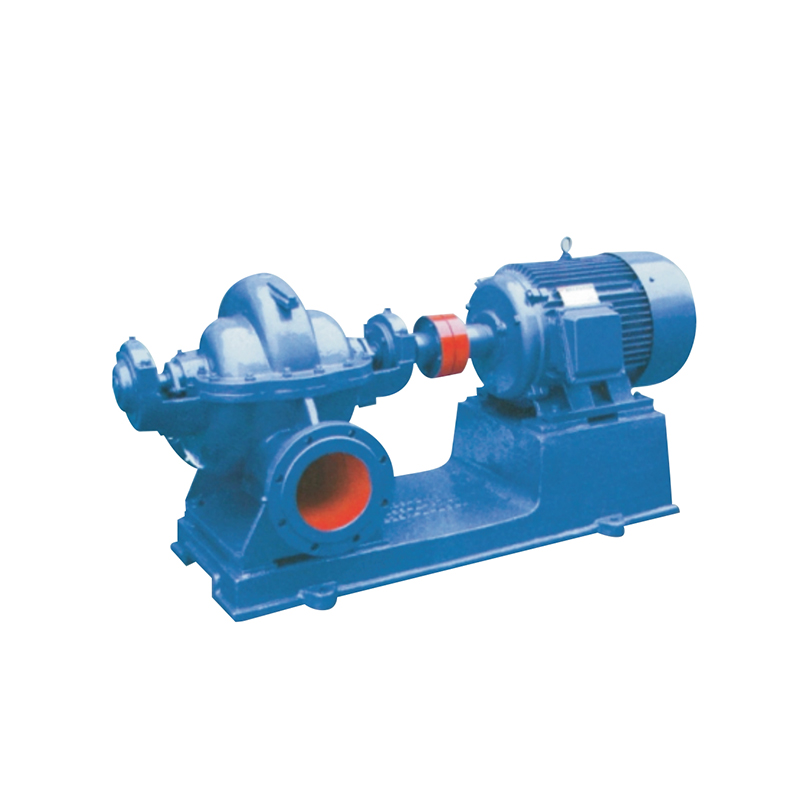

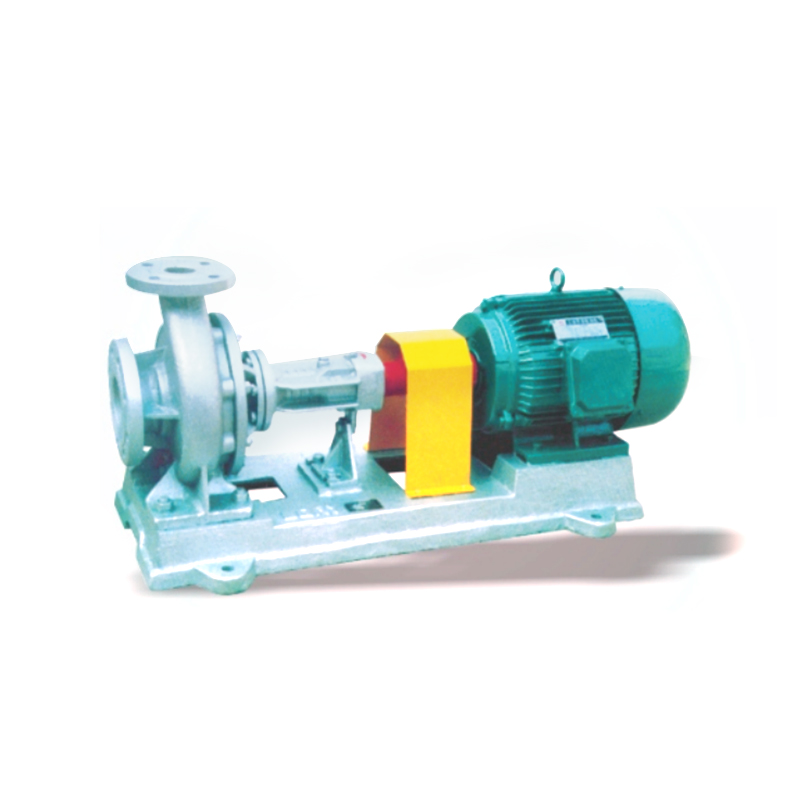

- Centrifugal Pumps

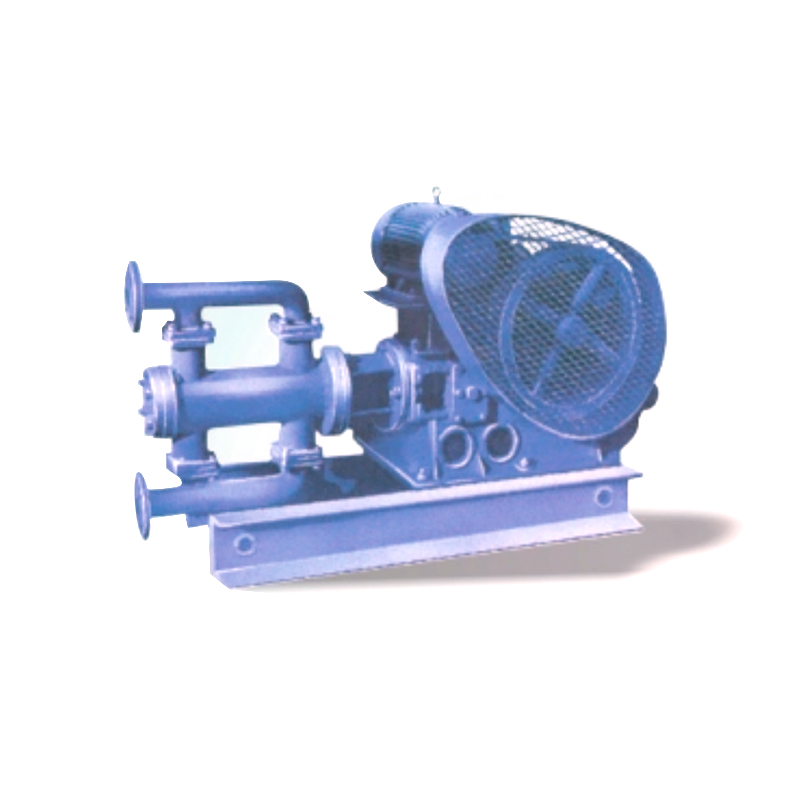

- Self-Priming Pumps

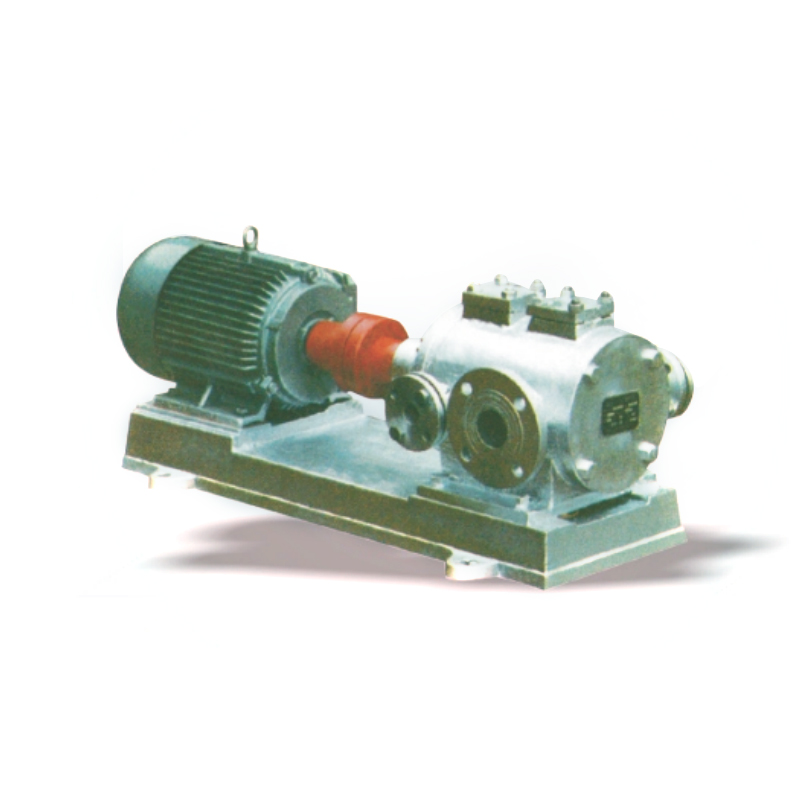

- Screw Pumps

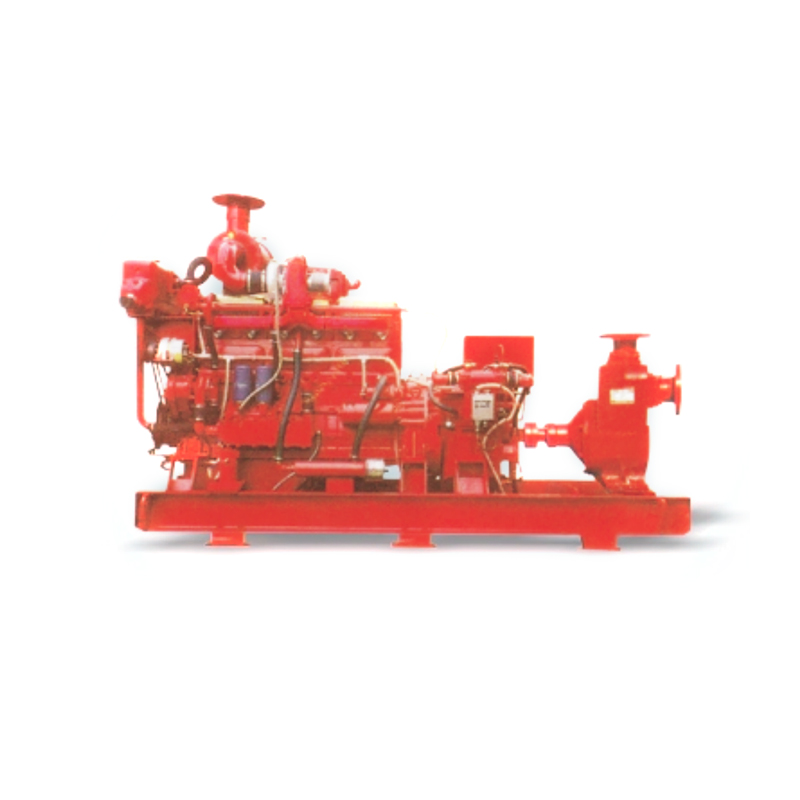

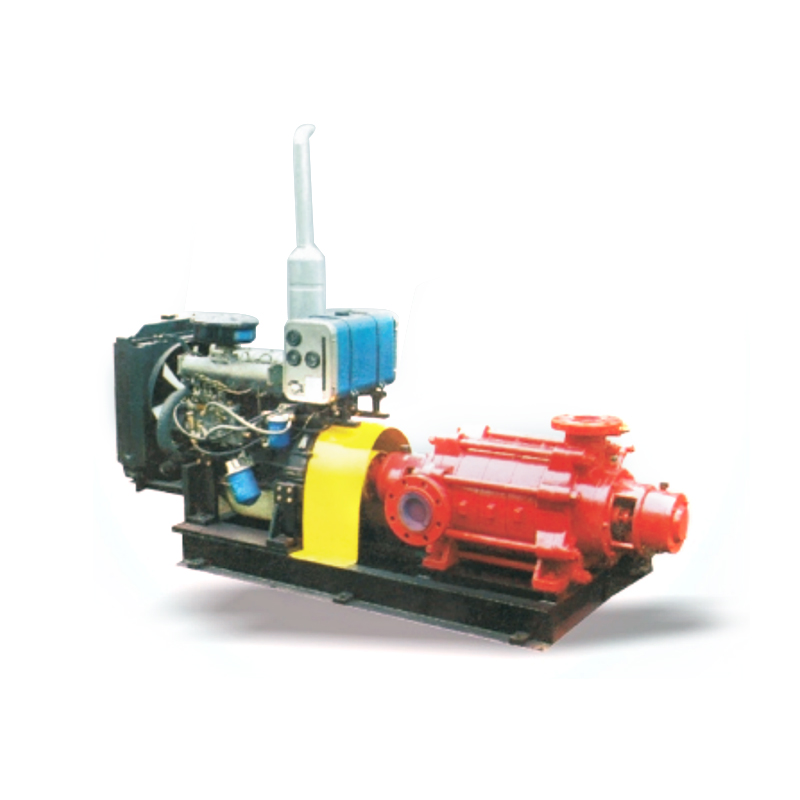

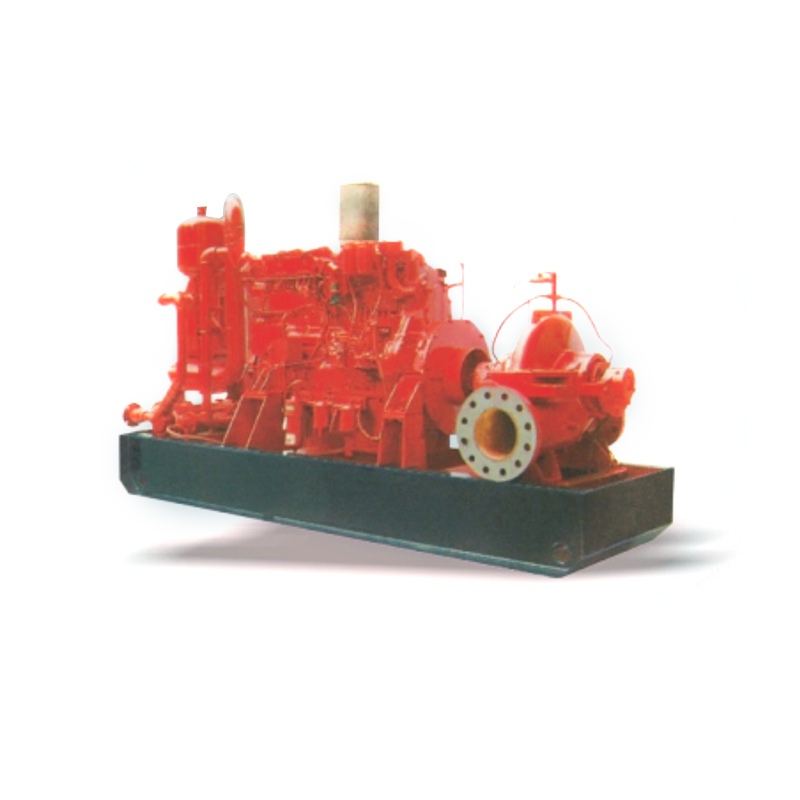

- Fire Pumps

- Sewage Pumps

- Diesel Engine Pump Sets

- Electrical Control Cabinets

- Irrigation Pumps

- Aquaculture Water Pumps

- Booster Pumps

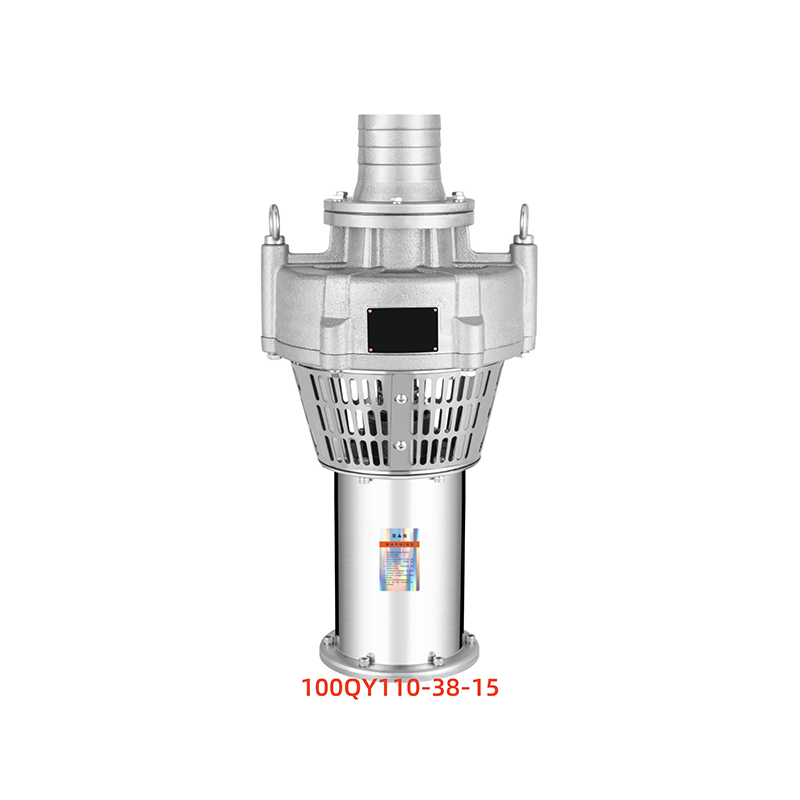

- Submersible Pumps

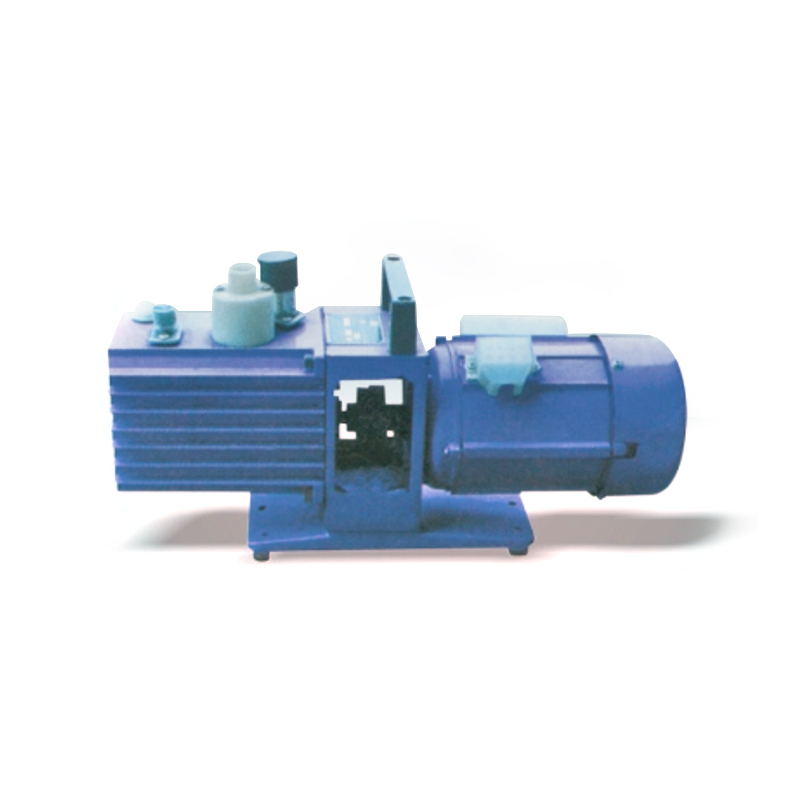

- Vacuum Pumps

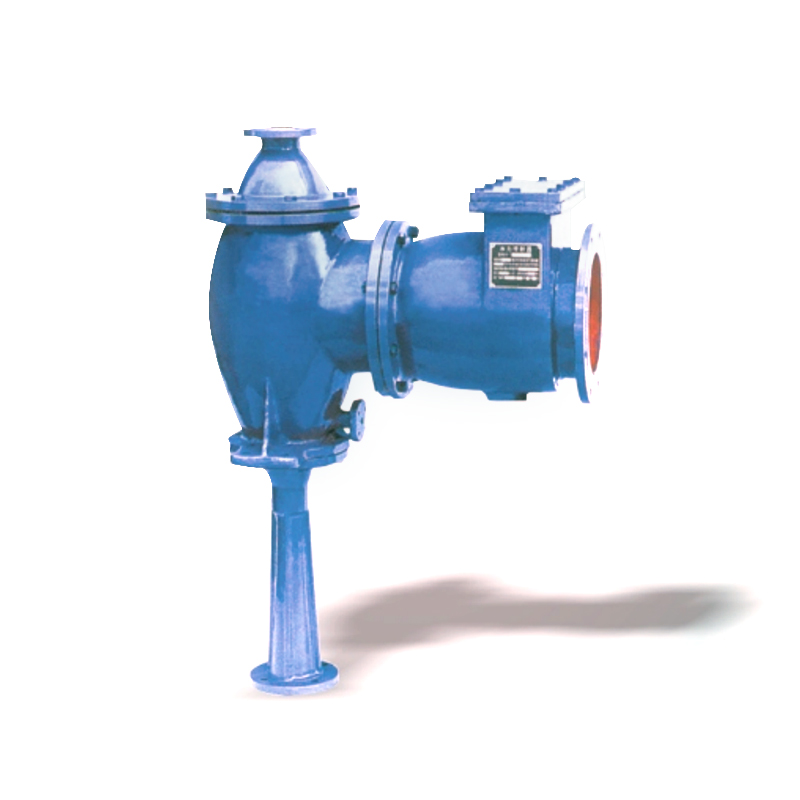

- Industrial Pumps

- Pump Accessories

Leading the innovation of fluid technology, we are proud to launch a new generation of water pump solutions. Not only does it have excellent water flow delivery capabilities and achieve precise flow control, but it also achieves a milestone leap in energy efficiency and environmental protection.

-

/ 01 Experience/ 02 Quality

The quality inspection department strictly monitors every production link and the factory inspection rate is 100%.

Our products are your ideal solution.

-

Garden

Efficient irrigation is achieved by pumping water from water sources to ensure plant growth.

-

Farms

Used for water circulation, oxygenation and feed delivery. The water pump is used to circulate and filter the water in the breeding pond to keep the water clean.

-

Wastewater Treatment Plants

The pump industry plays a key role in wastewater treatment plants, mainly used for the lifting, transportation and circulation of sewage.

-

Fountain

Water is pumped from a reservoir or circulation system and pressurized to create a variety of fountain water effects, such as gushing fountains, atomization or water curtains.

-

Swimming Pool

The pool water is pumped and transported to the filtration system to remove impurities and pollutants to ensure clean water quality.

Play Full Video

Play Full Video

-

0 m²

Factory Area

-

0 +

Industry Experience

Zhejiang Chuangken Fluid Co., Ltd. is a technology-innovative enterprise that combines research and development with production, specializing in the production of multistage pumps, centrifugal pumps, fire pumps, sewage pumps, complete sets of water supply equipment, control cabinets, etc. It has a long production history, excellent technical personnel, superb production equipment and perfect testing methods.

Learn about our industry exhibition information and recent events in our company.

-

Single-stage Single-suction Centrifugal Pumps are widely used in industrial and commercial applications where reliable fluid transfer is essential. These pumps operate using a single impeller to generate flow, drawing liquid from one suction point and delivering it efficiently to the discharge. The design simplicity of single-stage single-suction pumps provides reliability, easy maintenance, and predictable performance, making them a preferred choice for a wide range of operations, including water supply, irrigation, HVAC systems, and chemical transfer. Manufacturers of these pumps focus on precision engineering and material quality to ensure consistent operation. Each pump undergoes rigorous testing to verify flow rates, pressure stability, and mechanical integrity. Quality control measures guarantee that the pump delivers continuous performance over long operational periods, even under demanding conditions. Operators rely on the combination of mechanical simplicity and engineering precision to minimize downtime and operational disruptions. Single-stage single-suction centrifugal pumps are designed for easy installation and maintenance. Compact dimensions and straightforward piping connections allow operators to integrate the pumps quickly into existing systems. Modular components such as impellers, bearings, and seals can be replaced efficiently, reducing maintenance time and extending service life. The simplicity of design also reduces the need for specialized training, allowing operational staff to manage routine maintenance effectively. Detailed manuals and accessible control panels further support smooth operation, helping operators monitor pump performance and respond quickly to any irregularities. The versatility of these pumps is another advantage. They can handle a wide range of fluid types, including clean water, light chemicals, and industrial liquids. Their adaptability allows them to serve various industries, including agriculture, municipal water supply, chemical processing, and industrial manufacturing. Operators appreciate the ability to rely on consistent flow and pressure without complex system modifications. The compact and efficient design allows integration in spaces with limited room, offering flexibility for retrofitting older systems or upgrading existing facilities. Efficiency is a key feature of single-stage single-suction centrifugal pumps. Impeller design and hydraulic engineering optimize fluid flow, minimizing energy consumption while maintaining pressure stability. The robust construction ensures minimal vibration and wear, supporting reliable long-term operation. Pumps are tested under various conditions to ensure they deliver consistent performance under fluctuating system demands. Built-in monitoring points allow operators to track flow and pressure easily, ensuring that the pump continues to function optimally in continuous operation environments. These pumps also support system stability. By maintaining steady flow and pressure, single-stage single-suction centrifugal pumps reduce stress on other equipment, such as piping networks, valves, and storage tanks. Their reliable operation ensures smooth integration into larger fluid management systems, enhancing overall system efficiency. Operators can coordinate pump operation across multiple units to balance load and prevent overuse, extending the service life of connected components. Operators often value the balance between performance and simplicity in these pumps. The design allows for predictable operation and straightforward troubleshooting. Advanced materials and precision engineering provide durability, allowing the pumps to operate effectively over extended periods with minimal maintenance. Training resources and clear operational guidelines also make these pumps user-friendly, reducing the likelihood of errors and improving maintenance efficiency. Single-stage single-suction centrifugal pumps provide essential support for industrial and commercial fluid systems. Their design, reliability, and ease of maintenance make them indispensable in applications that require consistent flow, operational stability, and efficient performance. By delivering dependable results across multiple industries, these pumps remain a fundamental component of modern fluid management. Their combination of adaptability, durable construction, and operational simplicity ensures that facilities maintain continuous fluid transfer, supporting daily operations and critical system functionality.

30 -

Multistage Pumps Factories play an essential role in modern industrial operations, producing pumps capable of handling high pressure and large volume applications. These factories focus on manufacturing multistage pumps designed to move fluids efficiently across multiple stages, making them suitable for applications such as water supply systems, industrial plants, and power generation. Factory operations emphasize precision engineering, ensuring that each pump meets strict performance standards. Production lines often include advanced machining, assembly, and testing equipment to maintain uniform quality across different models. The manufacturing process in Multistage Pumps Factories includes rigorous inspection at every stage. Each pump undergoes calibration, pressure testing, and performance verification to guarantee reliability. Skilled engineers collaborate with technicians to refine pump designs, ensuring efficiency and durability under heavy operational conditions. The combination of precision and robust testing allows these pumps to operate continuously for extended periods without significant performance loss. Multistage Pumps Factories often accommodate customization, allowing clients to specify flow rate, head, and material requirements. This flexibility ensures that pumps fit the exact needs of different industrial projects, from municipal water distribution to chemical processing. Operators value pumps that maintain efficiency while meeting specific environmental or operational constraints. Many factories also provide guidance on optimal installation practices, including piping configuration, alignment checks, and vibration control, ensuring that pumps deliver consistent performance once deployed on-site. Technological advancements play a key role in factory operations. CNC machining, digital monitoring systems, and automated assembly lines reduce errors and enhance efficiency. Factories also integrate specialized test rigs to simulate real-world conditions, assessing how pumps respond to varying pressure, temperature, and flow rates. These measures ensure that each multistage pump performs consistently in demanding environments. Some factories further incorporate real-time monitoring devices to track pump operation during testing, allowing engineers to identify and correct any performance irregularities before delivery. Maintenance and service support are integral aspects of factory offerings. Many factories provide workshops for repairs and component replacements, allowing operators to extend the operational life of their pumps. Modular design enables easy replacement of critical parts, minimizing downtime and ensuring continuous operation in industrial settings. Service teams also advise on routine inspection schedules, lubrication requirements, and parts inventory management, helping operators maintain reliability over long-term usage. The versatility of multistage pumps produced in these factories allows their application across a wide range of industries. Water treatment plants, power generation stations, and industrial facilities rely on their ability to deliver high-pressure, consistent flow. Engineers emphasize the importance of precise pump selection to match operational requirements, highlighting the factory’s role in producing reliable equipment for complex systems. Factories also test pumps under different operational loads, confirming that each unit can adapt to variations in flow and pressure while maintaining optimal performance. Multistage Pumps Factories also prioritize energy efficiency and reduced operational wear. High-quality materials and carefully engineered components reduce friction and vibration, contributing to longer pump life and lower energy consumption. This attention to operational details ensures that pumps function reliably over long periods, meeting industrial expectations. Proper lubrication, balanced impellers, and vibration-dampening mounts further contribute to operational stability, reducing the need for frequent maintenance. Multistage Pumps Factories serve as a backbone of fluid management in various industries. Their combination of advanced manufacturing, quality control, and tailored solutions provides operators with pumps that meet demanding operational standards. Precision, reliability, and adaptability define the output of these factories, making them a critical part of modern industrial infrastructure. Operators benefit from both the performance of the pumps and the operational support provided by factories, ensuring that fluid systems remain functional, efficient, and durable across diverse applications.

23 -

Introduction to Jockey Pumps Jockey Pumps are integral components in fluid systems that require consistent pressure. Typically used in fire protection networks, they maintain pressure in pipelines when main pumps are inactive or demand is low. By automatically activating when pressure drops slightly, Jockey Pumps prevent unnecessary strain on larger pumps, prolonging their lifespan and ensuring reliable performance. Their role is critical in industrial, commercial, and residential systems where consistent pressure prevents malfunctions or emergency failures. Manufacturers produce these pumps with precision to ensure quick response times and smooth operation. Standard features include pressure sensors, automatic start/stop controls, and efficient motor designs that support long-term operation. Systems often include flexible mounting options and vibration-dampening components, reducing operational noise and mechanical stress. Jockey Pumps are designed for ease of installation. Modular piping connections, compact footprint, and accessible control panels allow quick integration into existing networks. Operators can adjust pressure settings and monitor pump operation without extensive technical knowledge, improving usability in commercial and industrial facilities. Technological Features and Improvements Recent developments in Jockey Pump design focus on efficiency, reliability, and low maintenance. Digital pressure sensors allow accurate monitoring of system conditions. Automatic controls reduce human intervention, improving responsiveness in critical systems. Manufacturers also optimize motor and pump designs to minimize energy consumption while maintaining consistent output. Testing is a crucial part of production. Jockey Pumps undergo simulated operational cycles to ensure durability under fluctuating pressures. These tests help refine components and improve system compatibility. Advanced sealing technologies and corrosion-resistant materials contribute to longevity, ensuring that pumps operate effectively in water, chemical, or mixed fluid networks. Some Jockey Pumps are equipped with diagnostic indicators that alert operators to abnormal conditions, including pressure drops, flow interruptions, or electrical irregularities. This feature enables quick troubleshooting without halting the entire system, adding practical value in facilities that operate continuously. Applications of Jockey Pumps Jockey Pumps are commonly deployed in fire protection, irrigation, and industrial fluid systems. In fire safety networks, they maintain pipeline pressure, allowing main pumps to operate only when high flow is needed. In industrial applications, they support consistent fluid delivery, preventing interruptions that could impact production or safety. Operators value Jockey Pumps for their reliability and energy efficiency. These pumps are designed to start and stop automatically, handling small pressure drops without operator intervention. In facilities with multiple pressure zones, Jockey Pumps can be configured to maintain uniform pressure across all points, enhancing system performance. Maintenance requirements are minimal. Routine inspection of seals, bearings, and motor components is sufficient to keep pumps in good working condition. Accessibility of components reduces downtime and simplifies preventive care, which is particularly important in facilities that cannot afford extended interruptions. Operational Impact Jockey Pumps contribute to the stability and efficiency of fluid systems in various facilities. By maintaining system pressure, they reduce wear on larger pumps and prevent unnecessary cycling. This capability supports operational continuity, particularly in industrial plants, commercial complexes, and residential high-rise buildings. Facilities rely on Jockey Pumps to ensure that water or fluid systems function correctly under normal and emergency conditions. Installation and maintenance practices provided by manufacturers improve safety and operational consistency. The combination of precise control, durable construction, and flexible deployment makes Jockey Pumps an essential component in maintaining reliable fluid pressure across diverse applications.

16 -

Diesel Engine Pump Factory and Industrial Production Diesel Engine Pump Factories have become key players in modern industrial production. These facilities focus on manufacturing pumps that provide reliable water, fuel, and fluid management solutions. The diesel engine-driven pumps produced at these factories are widely used in construction, agriculture, and emergency systems, reflecting a growing reliance on efficient, dependable machinery. Factories invest in advanced assembly lines and precision tools to maintain consistent quality and output, ensuring their products meet industrial standards across diverse sectors. The production process integrates strict quality checks at every stage. From engine calibration to pump testing, factories aim to guarantee operational reliability under demanding conditions. Manufacturing teams collaborate closely with engineering departments to refine designs, improve efficiency, and reduce downtime in real-world applications. This focus ensures that the diesel engine pumps can handle continuous operation while delivering performance that industrial users expect. Many factories also emphasize customization, providing pumps that match client specifications for capacity, engine size, and fluid type. This flexibility allows diesel engine pumps to serve specialized applications, from remote irrigation projects to industrial fuel transfer operations. Operators appreciate the ability to select pumps tailored to their operational environment. Technological Advancements in Diesel Engine Pump Factories Modern Diesel Engine Pump Factories increasingly adopt technology to enhance production. Automated assembly equipment, digital monitoring, and predictive maintenance systems help factories streamline operations and reduce potential errors. Technological improvements also extend to the engines themselves. Fuel efficiency, emissions control, and vibration reduction are addressed through design updates and component optimization. Factories also integrate testing facilities that simulate operational conditions. Pumps undergo stress testing to ensure durability and consistent performance. Data collected from these tests is analyzed to improve future models, aligning production with evolving industrial demands. Technology not only enhances output but supports operational safety by ensuring engines and pumps operate reliably under varying load conditions. Many factories maintain workshops for repairing or upgrading older diesel engine pumps. This service helps clients extend the operational life of their equipment, maintaining performance without the need for immediate replacement. Maintenance operations also offer insight into common wear patterns, guiding incremental improvements in design. Diesel Engine Pumps in Industrial Applications The diesel engine pumps produced in these factories are central to a variety of applications. They are used in irrigation systems, construction sites, and industrial plants, providing reliable water or fluid movement when electricity is unavailable or unreliable. Emergency services often rely on these pumps for firefighting or disaster response, where rapid deployment and consistent operation are critical. Industrial users benefit from the durability of these pumps. Diesel engine designs allow machines to operate continuously for extended periods, handling large volumes of fluid without frequent maintenance. Factories focus on building pumps that balance power, efficiency, and reliability, ensuring they meet diverse industrial requirements. Operators also value the simplicity of engine controls, which reduce the need for specialized training. Many diesel engine pumps are equipped with modular components, allowing quick replacement of parts such as pistons, seals, or valves. This modularity minimizes downtime in operations that cannot afford interruptions, such as agricultural irrigation during peak season or fuel transfer during industrial processes. Market and Operational Impact Diesel Engine Pump Factories influence industrial operations through reliable production and maintenance support. Their output affects infrastructure projects, agricultural efficiency, and emergency response capabilities. Operators rely on the consistent performance of diesel engine pumps for daily tasks, highlighting the importance of factory standards and quality control. The attention to operational precision and robust construction ensures that diesel engine pumps handle demanding conditions with minimal intervention. Factory staff often provide technical guidance on pump installation, engine tuning, and routine inspections. This combination of manufacturing quality and operational support strengthens the role of diesel engine pumps in industries that require consistent, dependable fluid management.

09 -

The constant pressure water supply system has become a significant development in modern water distribution, offering reliable and efficient solutions to meet the increasing demand for water in both urban and rural areas. This system, designed to maintain a consistent water pressure regardless of fluctuations in water demand, has gained popularity due to its numerous advantages in terms of efficiency, energy savings, and user satisfaction. At the core of the constant pressure water supply system is the use of variable frequency drive (VFD) pumps. These pumps adjust their speed based on real-time water demand, ensuring that water pressure remains stable even when the demand varies throughout the day. Unlike traditional water supply systems that rely on a fixed-speed pump, the VFD pumps can automatically increase or decrease their speed in response to changes in pressure. This makes the system more responsive to varying water usage, avoiding pressure surges or drops that can lead to problems such as pipe bursts or inconsistent water flow. The primary benefit of a constant pressure system is its ability to maintain a steady water pressure. For households and industries that rely on water for daily operations, a steady flow is essential. Fluctuating water pressure can cause inconvenience, such as weak showers, slow-running faucets, or malfunctioning appliances. By providing a consistent flow, a constant pressure water supply system enhances comfort and ensures that users receive an uninterrupted supply of water. Energy efficiency is another significant advantage of this system. Traditional water supply systems often waste energy by using pumps that run at full speed regardless of demand, leading to unnecessary power consumption. With a constant pressure water supply system, the VFD pump operates at varying speeds depending on the actual water demand, consuming only the energy necessary for the task at hand. This not only reduces electricity costs but also contributes to a more sustainable water supply system by lowering the overall carbon footprint. The constant pressure water supply system also helps extend the lifespan of plumbing infrastructure. By regulating water pressure, the system reduces the risk of water hammering, a phenomenon where a sudden change in pressure causes pipes to vibrate and potentially lead to leaks or damage. The constant and controlled pressure helps minimize wear and tear on pipes, pumps, and valves, contributing to fewer maintenance requirements and longer service life for the entire water supply network. In addition to residential and industrial use, the constant pressure water supply system has found applications in agricultural irrigation, where consistent water pressure is crucial for efficient water distribution. By maintaining a steady pressure, the system ensures that water is evenly distributed across crops, improving irrigation efficiency and reducing water wastage. This is particularly beneficial in areas where water resources are scarce and conservation is a priority. While the initial investment in installing a constant pressure water supply system may be higher compared to traditional systems, the long-term benefits outweigh the costs. The reduced energy consumption, fewer maintenance requirements, and improved user experience make it a worthwhile investment for both residential and commercial properties. The constant pressure water supply system is a modern solution that addresses various challenges associated with water distribution. Its ability to maintain consistent pressure, reduce energy consumption, and extend the lifespan of infrastructure makes it an attractive option for homes, businesses, and agricultural applications alike.

02 -

How the Energy-Saving Constant Pressure Water Supply System Works At the core of an energy-saving constant pressure water supply system is the integration of advanced pump technology and pressure sensors. Unlike traditional water supply systems that operate at fixed speeds or use a single, large pump, these systems adjust their output based on real-time demand. The system’s pump is equipped with a variable frequency drive (VFD) that allows the pump to operate at different speeds, depending on the pressure requirements. This flexibility ensures that the water supply remains constant, even when demand fluctuates. The pressure sensors monitor the water pressure in the system, sending feedback to the VFD. When the pressure drops, such as during peak water usage times, the VFD increases the pump speed to restore the desired pressure. Conversely, when water demand decreases, the pump speed is reduced, saving energy. This dynamic response helps to maintain consistent water pressure, while minimizing energy consumption, making it an ideal solution for both residential and commercial water supply systems. Key Benefits of Energy-Saving Constant Pressure Water Supply Systems One of the main advantages of these systems is their ability to significantly reduce energy consumption. Traditional water pumps often operate at a constant speed, regardless of water demand, leading to unnecessary energy use during low-demand periods. In contrast, energy-saving constant pressure systems use variable-speed pumps that adjust their operation based on actual needs, ensuring that energy is only used when required. This dynamic energy use can result in substantial savings over time, especially in large facilities or residential complexes where water demand can vary throughout the day. In addition to energy savings, these systems also contribute to more stable water pressure. Traditional water systems can experience fluctuations in pressure, especially during periods of high demand, leading to inconsistent water flow. The constant pressure system addresses this issue by maintaining a steady and reliable water supply, regardless of usage patterns. This is particularly important in applications where water pressure consistency is essential, such as in irrigation systems, HVAC systems, and residential buildings. The system's ability to adjust pump speeds reduces wear and tear on the equipment. Constant-speed pumps often experience greater mechanical strain, as they are forced to work at full capacity even when it’s not necessary. Variable-speed pumps, on the other hand, operate more efficiently, leading to less frequent maintenance needs and longer equipment lifespans. Applications of Energy-Saving Constant Pressure Water Supply Systems Energy-saving constant pressure water supply systems are versatile and can be used in various sectors, including residential, commercial, and industrial applications. In residential settings, these systems provide homeowners with a reliable and efficient water supply, ensuring consistent pressure for tasks like showering, washing, and gardening. The energy-saving feature is especially beneficial in households where water demand can vary throughout the day, helping reduce electricity costs. In commercial buildings, hotels, and large office complexes, maintaining consistent water pressure is crucial for both comfort and operational efficiency. A fluctuating water supply can lead to inconvenience, especially in high-traffic areas. The energy-saving constant pressure system offers a solution that ensures water pressure remains constant while reducing energy consumption. This system is also beneficial for larger facilities such as hospitals, schools, and shopping malls, where water demand is high and continuous. Industrial applications also benefit from energy-saving constant pressure water supply systems, particularly in factories and production facilities where water is used for cooling, cleaning, or processing. The ability to maintain constant pressure without wasting energy makes these systems an ideal choice for industries aiming to improve operational efficiency and reduce their environmental footprint.

25

浙公网安备33032402001888号

浙公网安备33032402001888号