Full Automatic Constant Pressure Variable Frequency Water Supply Equipment is a new generation of hi...

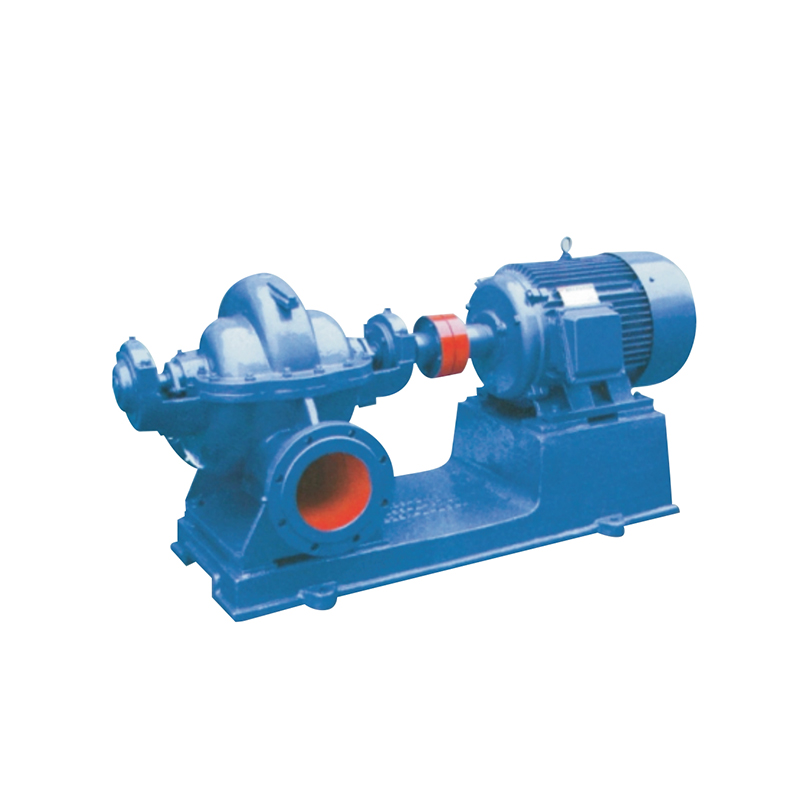

See DetailsRising Demand for Double Suction Centrifugal Pumps: Boosting Industrial Efficiency Through Balanced Performance

Industry News-As industrial and municipal infrastructure becomes more complex and capacity requirements grow, the demand for high-volume, high-efficiency fluid handling equipment is steadily increasing. Among the technologies gaining traction in this arena is the Double Suction Centrifugal Pump—a robust and highly efficient solution for handling large flow rates with stable hydraulic performance. As industries aim to minimize downtime, reduce energy costs, and enhance system reliability, the double suction centrifugal pump stands out as an essential asset in modern fluid management.

What Is a Double Suction Centrifugal Pump?

A Double Suction Centrifugal Pump is a type of single-stage centrifugal pump specifically designed to allow fluid to enter the impeller from both sides simultaneously. This balanced suction arrangement reduces axial thrust on the impeller and improves the hydraulic efficiency of the pump, making it particularly well-suited for large-scale fluid transport.

Compared to standard end-suction pumps, double suction designs can handle higher flow rates with smoother operation. The symmetrical design of the impeller not only enhances performance but also reduces mechanical stress, contributing to the pump's longevity and reliability in continuous-duty applications.

Core Design Features and Advantages

The distinctive construction of a double suction centrifugal pump offers a variety of engineering and operational benefits:

Balanced Hydraulic Forces: By allowing fluid to enter from both sides of the impeller, the pump axial thrust, reducing wear on bearings and mechanical seals.

High Flow Capacity: Double suction pumps are engineered to accommodate large volumes of liquid, making them ideal for applications where high capacity is required without sacrificing efficiency.

Horizontal Split Casing: Many models feature a horizontally split volute casing, which simplifies maintenance by allowing easy access to internal components without disconnecting the piping.

Reduced NPSH Requirements: The symmetrical suction design helps lower the Net Positive Suction Head (NPSH) requirement, decreasing the risk of cavitation and ensuring stable operation even under challenging suction conditions.

Improved Efficiency at Scale: While single suction pumps may become inefficient at high capacities, double suction designs maintain high efficiency across a broad flow range.

Why Industries Are Turning to Double Suction Pumps

The performance advantages of double suction centrifugal pumps translate into several real-world benefits for industrial and municipal operations:

Lower Operating Costs: Improved efficiency and reduced mechanical wear result in decreased energy consumption and maintenance expenditures over the pump’s lifecycle.

Reliable High-Volume Operation: Ideal for continuous operation in demanding environments, these pumps ensure stable pressure and flow with fluctuations.

Long Service Life: The balanced design reduces stress on critical components, extending the overall durability of the pump, especially in mission-critical systems.

Easy Servicing: The split-case design simplifies routine inspections and repairs, system downtime and improving productivity.

Scalability: Whether in power plants, water treatment facilities, or petrochemical plants, double suction pumps scale efficiently to meet growing capacity needs.

Application Sectors Driving Adoption

The versatility and high flow capacity of double suction centrifugal pumps make them a choice across a wide range of industries:

Municipal Water Supply & Distribution: These pumps are used in waterworks to transport large volumes of clean water over long distances with pressure loss.

District Heating and Cooling: In large-scale HVAC systems, double suction pumps provide stable flow to maintain consistent temperatures in buildings and campuses.

Power Generation: Thermal and nuclear power plants utilize these pumps in boiler feed systems, cooling water loops, and condensate extraction due to their efficiency and reliability.

Industrial Manufacturing: From pulp and paper mills to textile factories, double suction pumps handle process water, wastewater, and cooling fluids with ease.

Irrigation and Agriculture: For extensive farmland and greenhouse operations, the pump ensures consistent water delivery with mechanical intervention.

浙公网安备33032402001888号

浙公网安备33032402001888号