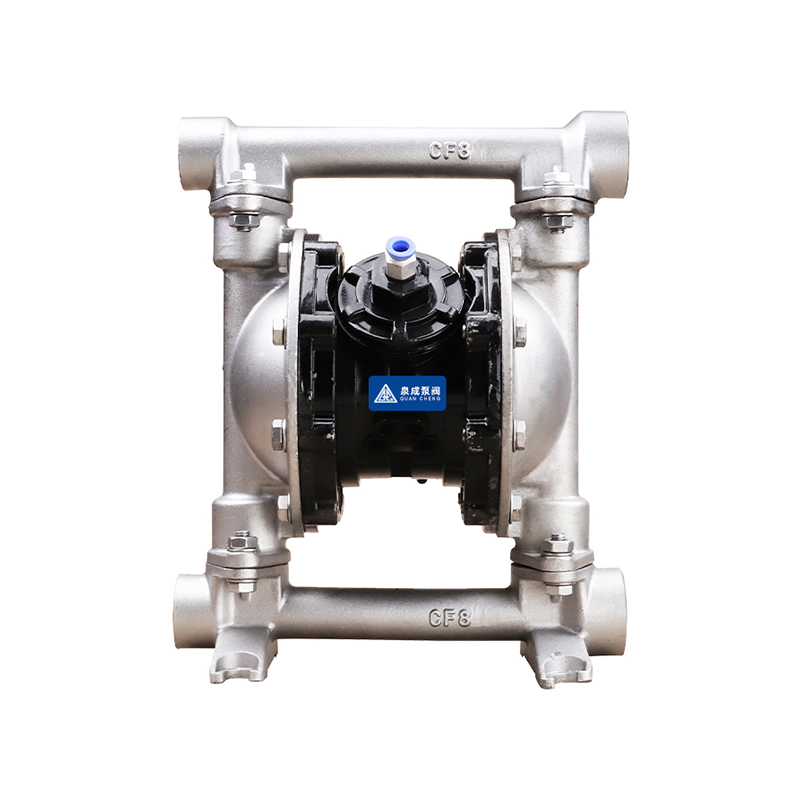

The QBK Food Grade Air Operated Double Diaphragm Pump is a newly developed line of pumps, which is also the next generation of technology. It boasts a long service life and continuous operation, capable of conveying difficult-to-flow mediums. This pump combines the advantages of self-priming pumps, submersible pumps, shield pumps, slurry pumps, and impurity pumps, among others.

Working Principle

Each of the two symmetrical pump chambers is equipped with a diaphragm, which is connected by a central coupling rod. Compressed air enters through the pump inlet valve and fills one chamber, causing the diaphragm to move. The air in the opposite chamber is expelled. Once the diaphragm reaches its limit, the gas distribution components automatically redirect compressed air into the other chamber, reversing the diaphragm’s movement. This ensures continuous, synchronized reciprocating movement of the two diaphragms.

Compressed air enters the valve, causing the diaphragm to move in one direction, which generates suction in the chamber, allowing the medium to enter. The ball valve then closes as the medium is drawn in. The medium is discharged by the diaphragm’s extrusion, causing the ball valve to open and close, preventing backflow. This process allows the medium to continuously enter from the inlet and be discharged from the outlet.

Main Advantages

By utilizing air power, the flow rate automatically adjusts based on the export resistance, making it suitable for high-viscosity fluids.

In flammable and explosive environments, the pump is reliable, low-cost, spark-free, and does not overheat.

The compact design of the pump makes it easy to move, with no need for a foundation. It is convenient to install and cost-effective, and can be used as a mobile conveying pump.

The diaphragm pump can be completely separated from the external environment, making it ideal for processing dangerous or corrosive materials.

The low shear force of the pump minimizes the physical impact on the medium, making it suitable for conveying unstable chemical fluids.

Main Applications

Pumping peanut butter, pickles, mashed potatoes, small sausages, jam, apple pulp, chocolate, etc.

Pumping paint, tree resin, pigments.

Pumping adhesives and various types of glue.

Pumping various types of glaze for tiles, ceramics, and pottery.

After drilling an oil well, pumping sediment and grouting.

Pumping various emulsions and fillers.

Pumping various types of wastewater.

Using the pump to clear sludge and wastewater from oil tankers and barges.

Pumping hop and yeast slurries, syrups, and molasses.

Pumping accumulated water from mines, tunnels, pits, mineral processing, and slag; pumping cement slurry and grout.

Pumping various rubber slurries.

Pumping abrasives, corrosive agents, petroleum, mud, cleaning oil sludge, and general containers.

Pumping various highly toxic, inflammable, and volatile liquids.

Pumping various strong acids, strong bases, and highly corrosive liquids.

Pumping various high-temperature liquids, with a maximum tolerance of 150°C.

Used as a pre-pressurizing device for various solid-liquid separation equipment.

浙公网安备33032402001888号

浙公网安备33032402001888号