Single-stage Single-suction Centrifugal Pumps are widely used in industrial and commercial applications where reliable fluid transfer is essential. These pumps operate using a single impeller to generate flow, drawing li...

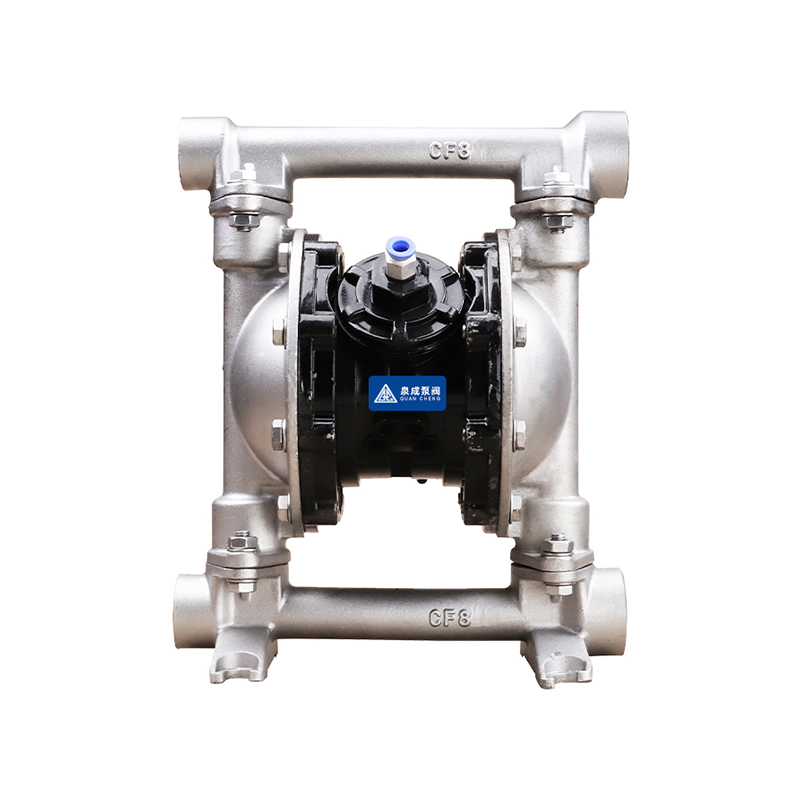

READ MOREDiaphragm Pumps Manufacturers

Diaphragm pumps, a specialized type of positive displacement pump, offer versatile, reliable, and efficient solutions for fluid transfer across numerous industries. These pumps rely on a diaphragm, a flexible membrane that moves back and forth, changing the volume of the pump chamber to draw in and expel fluids. With their ability to handle a wide range of liquids, including abrasive, viscous, and hazardous substances, diaphragm pumps have become an indispensable tool in many sectors such as food processing, chemical manufacturing, wastewater management, environmental protection, and paper production.

Key Features and Benefits:

1. Versatility in Materials:

Diaphragm pumps are known for their adaptability to different materials. They are typically made from durable materials such as plastics, aluminum alloys, cast iron, stainless steel, and fluoroplastics. These materials ensure that diaphragm pumps can be tailored to suit various application requirements, whether it’s the need for corrosion resistance, high strength, or chemical compatibility.

2. Wide Range of Diaphragm Materials:

The diaphragm material is crucial in determining the pump’s compatibility with different fluids. Common diaphragm materials include nitrile rubber, neoprene rubber, fluorocarbon rubber, PTFE (polytetrafluoroethylene), and PVDF (polyvinylidene fluoride). Each material is carefully selected based on the chemical composition and temperature of the liquid being transferred. This allows diaphragm pumps to efficiently handle everything from non-corrosive liquids to highly abrasive or aggressive chemicals.

3. Power Options:

Diaphragm pumps come in two primary power options: air-operated and electric.

Air-Operated Diaphragm Pumps: These pumps are powered by compressed air, making them ideal for environments where electrical power is unavailable or hazardous. Air-operated diaphragm pumps are highly energy-efficient and capable of running continuously without overheating, making them good for demanding industrial applications.

Electric Diaphragm Pumps: Powered by electricity, these pumps offer precise control and are typically used in environments where compressed air is not feasible. Electric diaphragm pumps can be integrated into automated systems and are ideal for environments with stable power supply.

4. Low Maintenance and Durability:

Diaphragm pumps are designed for longevity and minimal maintenance. Their simple design, which eliminates the need for mechanical seals, results in reduced wear and tear. This also ensures that the pumps maintain high efficiency over time, leading to lower operational costs and fewer breakdowns.

5. Self-Priming and Dry Running Capabilities:

Another distinct advantage of diaphragm pumps is their self-priming ability, which means they can operate without needing to be flooded with liquid before starting. Additionally, many diaphragm pumps are capable of dry running, making them ideal for environments where the pump may occasionally run without liquid.

6. Applications Across Industries:

Food and Beverage Industry: Diaphragm pumps are used for transferring ingredients like sauces, oils, syrups, and dairy products. Their sanitary design ensures compliance with food safety standards, preventing contamination.

Chemical Industry: In the chemical sector, diaphragm pumps handle acids, alkalis, and solvents, ensuring that these aggressive substances are safely pumped without compromising equipment longevity.

Wastewater Treatment: With the ability to pump sludge, chemicals, and wastewater, diaphragm pumps help maintain efficient water treatment processes.

Environmental Protection: Used to pump hazardous chemicals, waste products, and pollutants, these pumps contribute significantly to environmental conservation efforts.

-

-

Multistage Pumps Factories play an essential role in modern industrial operations, producing pumps capable of handling high pressure and large volume applications. These factories focus on manufacturing multistage pumps ...

READ MORE -

Introduction to Jockey Pumps Jockey Pumps are integral components in fluid systems that require consistent pressure. Typically used in fire protection networks, they maintain pressure in pipelines when main pumps are ina...

READ MORE

浙公网安备33032402001888号

浙公网安备33032402001888号