Operating Conditions

Liquid Characteristics: The ZS Stainless Steel Horizontal Single-stage Centrifugal Pump is suitable for clean, thin liquids that do not contain solid particles or fibers.

Temperature Range: The liquid temperature should range from -20°C to +100°C.

Ambient Temperature: The maximum ambient temperature is +40°C.

Altitude and Pressure: The maximum altitude is 1000 meters, and the system's maximum pressure is 10 bar.

Product Advantages

Resistant to various corrosive media, including acids, alkalis, salts, and solutions, with nice anti-corrosion properties.

Effectively improves energy efficiency and reduces energy consumption for users.

Features high flow rate, high head, stable operation, and low noise.

Simple structure, easy disassembly, and nice performance in daily maintenance, upkeep, and cleaning.

Made using stainless steel sheet stamping and welding processes, resulting in an attractive and lightweight design.

Highly efficient, durable, resistant to light corrosion, and low noise.

High temperature and pressure resistance, ensuring a long operational lifespan.

Applications

The ZS Stainless Steel Horizontal Single-stage Centrifugal Pump is a versatile product suitable for a wide range of applications. It can transport various media, including water or industrial liquids, and is adaptable to different temperature, flow, and pressure ranges. Typical applications include:

Water Supply: Filtration, transportation, and zonal water delivery, as well as main pipeline boosting in water plants.

Industrial Boosting: Process water systems, cleaning systems.

Industrial Liquid Transportation: Boiler feed water, condensation systems, cooling and air conditioning systems, machine tool accessories, weak acid and alkali transport.

Water Treatment: Distillation systems or separators, swimming pools, etc.

Agricultural Irrigation, Medical and Health Industries, etc.

Installation Conditions

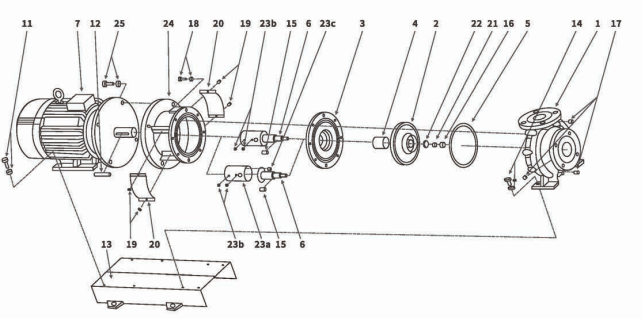

The ZS Stainless Steel Horizontal Single-stage Centrifugal Pump is a direct-coupled model, consisting of the pump, pump shaft, and standard motor.

The pump should be installed in a ventilated and frost-proof location.

The installation should ensure that the pump is not affected by the system piping tension during operation.

If the pump is installed outdoors, an appropriate cover must be provided to protect electrical components from water ingress or condensation.

Sufficient space should be left around the unit for inspection and maintenance.

Electrical connections should ensure that the pump is protected from phase loss, voltage instability, leakage, and overload.

The pump should be installed horizontally on a base, with the horizontal direction as the pump’s suction port and the vertical direction as the pump’s discharge port.

浙公网安备33032402001888号

浙公网安备33032402001888号