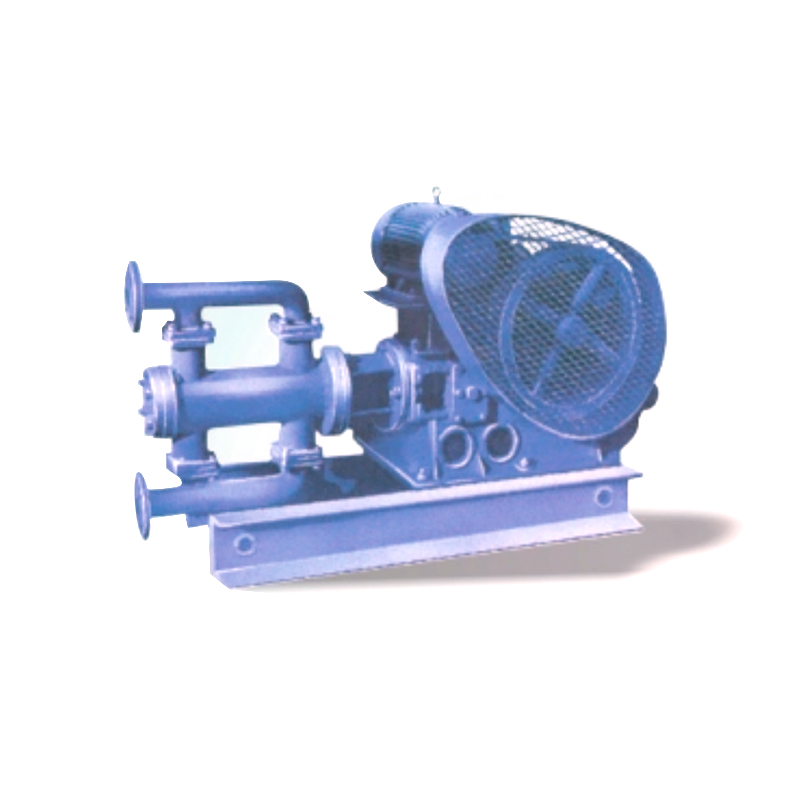

Single-stage Single-suction Centrifugal Pumps are widely used in industrial and commercial applications where reliable fluid transfer is essential. These pumps operate using a single impeller to generate flow, drawing li...

READ MOREIndustrial Pumps Manufacturers

Industrial pumps are critical components in a wide variety of industries, from oil and gas to water treatment, food and beverage, and pharmaceuticals. These powerful machines ensure that fluids, whether water, chemicals, oil, or slurry, move through systems safely and efficiently.

What Are Industrial Pumps?

Industrial pumps are mechanical devices used to move fluids or slurries from one location to another. They come in many different types and sizes, each designed for specific applications based on fluid type, viscosity, pressure, and flow rate requirements. These pumps work by converting mechanical energy into hydraulic energy, which then enables them to transport fluids through pipes or channels, overcoming resistance in the system such as friction, gravity, and pressure differences.

Industrial pumps are integral to a wide range of industries, including manufacturing, mining, chemical processing, water treatment, power generation, and more. Their versatility, durability, and efficiency make them a core component in operations that require continuous or high-volume fluid transfer.

Types of Industrial Pumps

Industrial pumps come in several types, each suited for specific fluid handling tasks. The two main categories are positive displacement pumps and dynamic pumps, with further subdivisions in each:

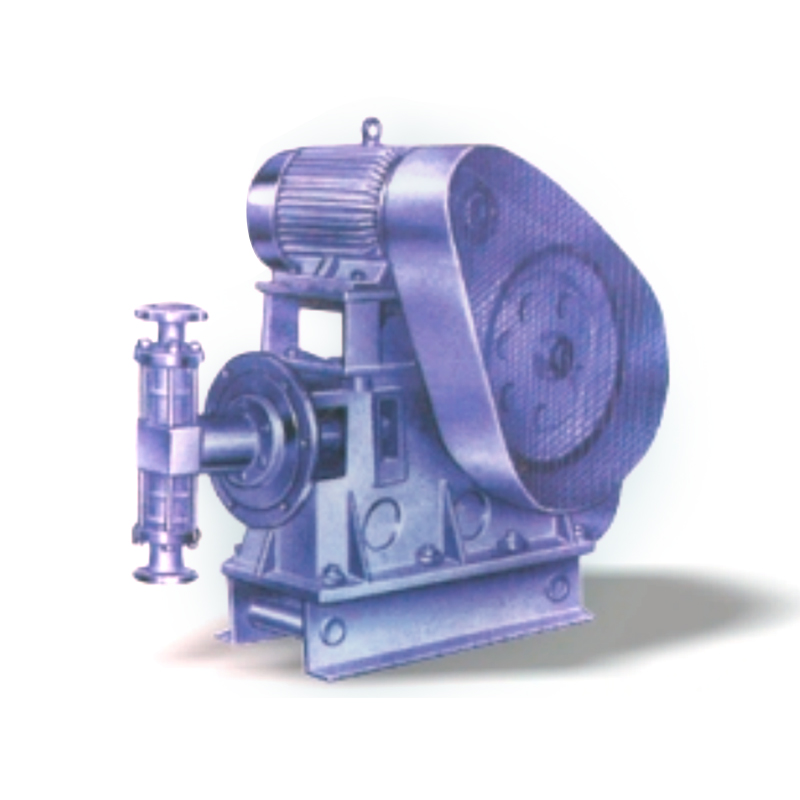

1. Positive Displacement Pumps

These pumps operate by trapping a fixed amount of fluid and forcing it through the system. They are ideal for applications where the flow rate must be consistent, and they are typically used for high-pressure or high-viscosity fluids. Types of positive displacement pumps include:

Gear Pumps: Commonly used for oil, fuel, and chemical pumping.

Diaphragm Pumps: Often used in food, beverage, and pharmaceutical industries.

Piston Pumps: good for high-pressure applications like hydraulic systems.

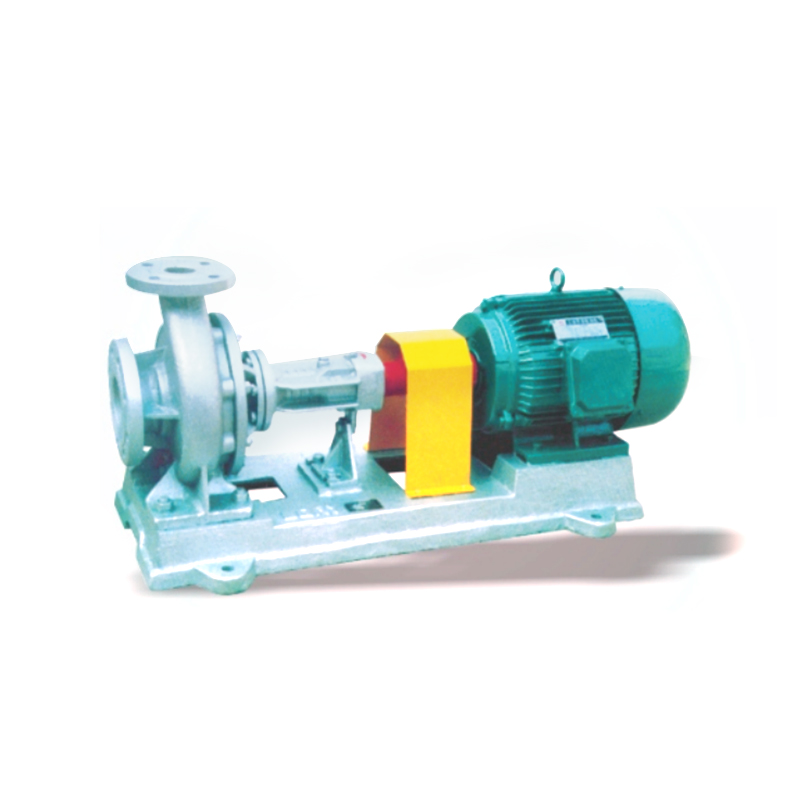

2. Dynamic Pumps

These pumps use kinetic energy to move fluids, typically at higher flow rates and lower pressures compared to positive displacement pumps. They are ideal for applications such as water transport, wastewater treatment, and chemical processing. Common types include:

Centrifugal Pumps: Widely used in water and sewage treatment, power generation, and HVAC systems.

Axial Flow Pumps: Often used in irrigation and drainage systems.

Radial Flow Pumps: Common in industrial applications where a high-pressure, low-flow system is needed.

Key Features and Benefits

1. Durability and Longevity

Built with robust materials such as stainless steel, cast iron, and high-performance alloys, industrial pumps are engineered to withstand harsh conditions. These include tough pressures, temperatures, and abrasive or corrosive materials. High-quality industrial pumps ensure long operational life, reducing the frequency of repairs or replacements.

2. Energy Efficiency

Modern industrial pumps are designed to be energy-efficient, which is critical in large-scale operations. By optimizing the pump’s performance, manufacturers can reduce energy consumption, lower operational costs, and decrease their carbon footprint. Features such as variable speed drives (VSDs) and automatic control systems help fine-tune pump operation, ensuring efficiency in varying conditions.

3. Improved Performance and Productivity

Industrial pumps are engineered to handle high flow rates and maintain stable pressure, ensuring smooth operations and minimizing downtime. Their consistent performance ensures that production processes continue seamlessly, enhancing productivity across various industries.

4. Easy Maintenance

modern industrial pumps are designed with ease of maintenance in mind. Features such as modular construction, simple disassembly, and interchangeable parts ensure that maintenance is quick and efficient, minimizing downtime and maintenance costs. Many pumps also feature built-in sensors that provide real-time data on pump performance, helping to predict when maintenance is required.

-

-

Multistage Pumps Factories play an essential role in modern industrial operations, producing pumps capable of handling high pressure and large volume applications. These factories focus on manufacturing multistage pumps ...

READ MORE -

Introduction to Jockey Pumps Jockey Pumps are integral components in fluid systems that require consistent pressure. Typically used in fire protection networks, they maintain pressure in pipelines when main pumps are ina...

READ MORE

浙公网安备33032402001888号

浙公网安备33032402001888号