The output pressure of each stage of the pump is 0.6MPa, with a head of 60m (for clean water). The self-priming height is generally 6m, and it is suitable for transporting media with a temperature of up to 80°C (special requirements can reach up to 150°C).

Because the stator is made from a variety of elastic materials, this pump is particularly suitable for handling high-viscosity fluids, as well as media containing solid particles or fibers, which are beyond the capabilities of typical pumps. The flow rate is directly proportional to the rotational speed.

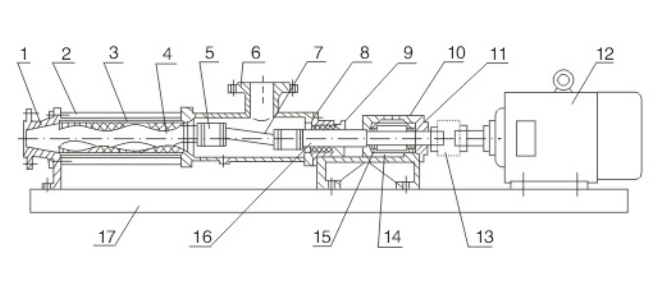

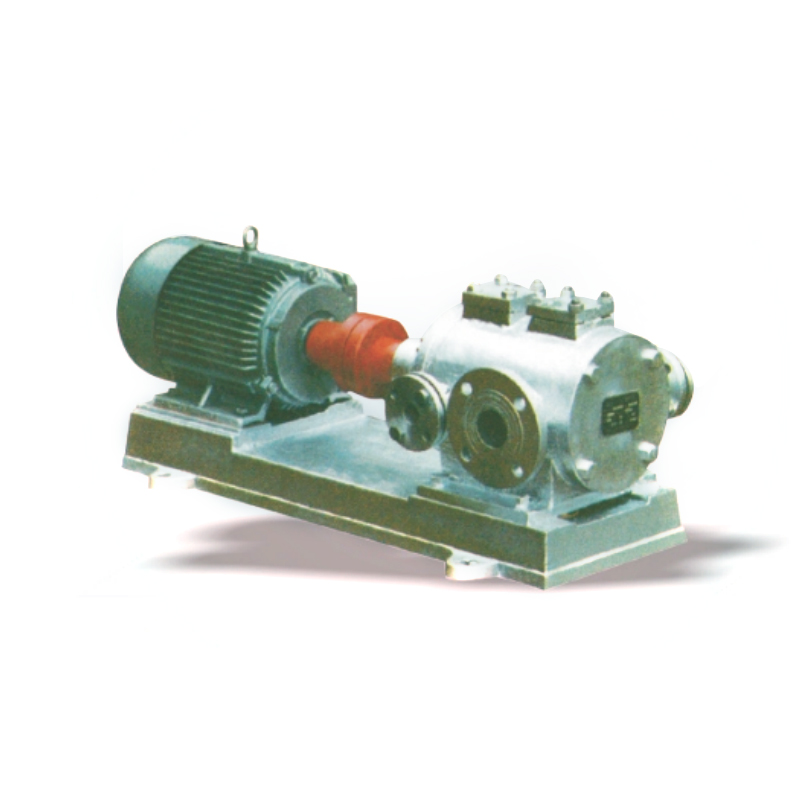

The pump can be driven via a coupling for direct transmission or by using a variable speed motor, V-belt, gearbox, or other speed-adjusting devices. The pump has few parts, a compact structure, a small volume, and is easy to maintain. The rotor and stator are the main wear parts, and the simple structure facilitates easy assembly and disassembly.

Application Range

The G Stainless Steel Single Screw Pump is a versatile, multi-purpose pump. The flow rate can be adjusted as required, and the running speed can be either high or low. The outlet pressure can be increased by adding more stages—each additional stage increases the pressure by 0.6MPa. It has a wide range of applications across various industries, including:

Environmental Protection: Transporting industrial wastewater, domestic sewage, muddy water containing solid particles and short fibers. It is particularly suitable for oil-water separators, plate and frame presses, etc.

Shipbuilding Industry: Transporting media such as bottom wheel cleaning fluids, oil-water mixtures, oil sludge, and oily wastewater.

Petroleum Industry: Transporting crude oil, crude oil-water mixtures, coal gas-water mixtures, and injecting polymers into formations, thereby reducing the cost of mechanical oil recovery, mining gas fields, and enhancing oil recovery.

Pharmaceutical and Daily Use Industries: Transporting various sticky pastes, emulsions, ointments, and cosmetics.

Food Canning Industry: Transporting viscous starches, edible oils, honey, syrups, jams, butter, surimi, and other byproducts.

Brewing Industry: Moving various fermented viscous slurries, concentrated distiller’s grains, grain residues, sauces, pulps, and mucilages containing solid particles.

Construction Industry: Spraying and transporting cement mortar, lime slurry, paint, and other pastes.

Mining Industry: Transporting groundwater and slurry containing solid particles from underground mines to the surface.

Chemical Industry: Transporting various suspensions, greases, colloidal pastes, adhesives, and other chemical media.

Printing and Paper Industry: Transporting high-viscosity inks, PVC polymer pastes, and various concentrations of pulp and short-fiber slurry.

Industrial Boilers and Power Plants: Transporting coal-water slurry for energy production.

浙公网安备33032402001888号

浙公网安备33032402001888号