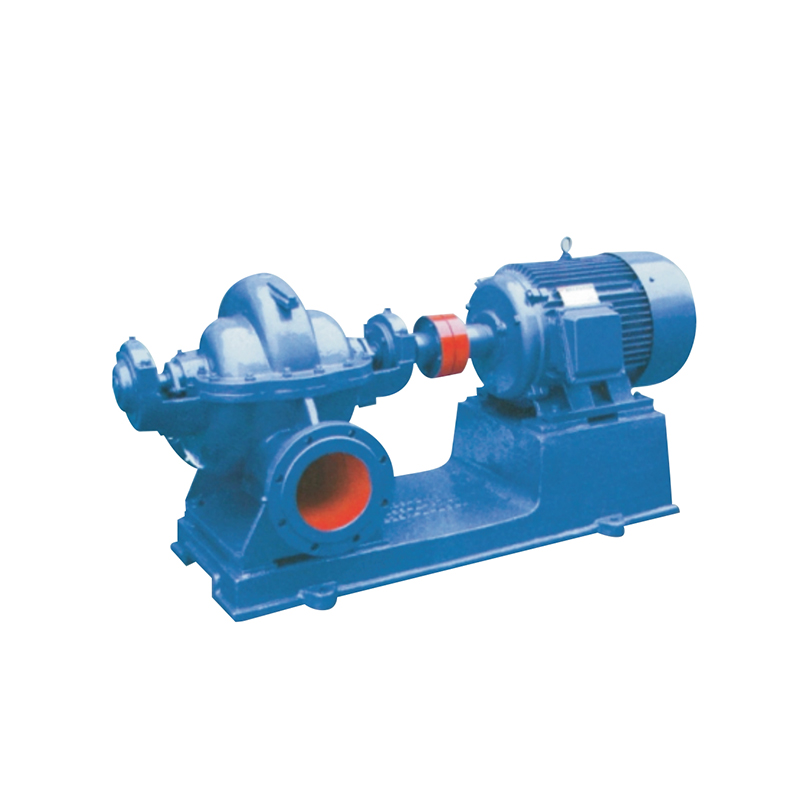

Single-stage Single-suction Centrifugal Pumps are widely used in industrial and commercial applications where reliable fluid transfer is essential. These pumps operate using a single impeller to generate flow, drawing li...

READ MORECentrifugal Pumps Manufacturers

Centrifugal pumps are engineered to move liquids using the principle of centrifugal force. By utilizing a high-speed rotating impeller, these pumps convert mechanical energy into kinetic energy, creating the force needed to propel liquids from one location to another. As the impeller spins, the liquid is thrown outward, creating a flow that pushes the liquid through the pump’s system and premierly toward its destination.

Key Features and Advantages

1. Simplicity in Design

One of the significant advantages of centrifugal pumps is their straightforward, robust design. The mechanism relies on a high-speed impeller that works within a casing, making it easy to operate and maintain. With fewer moving parts compared to other pump types, centrifugal pumps are inherently reliable, reducing the chance of failure.

2. Ease of Maintenance

Maintenance is one of the critical considerations for any industrial equipment, and centrifugal pumps shine in this area. Due to their relatively uncomplicated structure, these pumps are quick and easy to repair. Routine maintenance tasks such as cleaning, replacing worn-out seals, and inspecting the impeller can be done without major disruptions to the system.

3. Vibration-Free and Quiet Operation

The operational stability of centrifugal pumps is a significant benefit in many industries. These pumps are designed to function with minimal vibration, ensuring that they run smoothly without putting additional strain on supporting structures or other equipment. Moreover, the design helps in reducing noise levels, providing a quieter working environment.

4. Effective Sealing for Leak Prevention

Centrifugal pumps are designed with high-quality seals that help maintain the integrity of the system. The sealing mechanism prevents leaks, ensuring that the pumped liquid remains within the system and is safely transported. Whether dealing with water, chemicals, or other liquids, centrifugal pumps offer a reliable sealing solution to avoid spillage and contamination.

5. Low Energy Consumption and Cost-Effectiveness

Centrifugal pumps are among the energy-efficient pumps on the market. Their high efficiency leads to low energy consumption, making them an economical choice for long-term operation. The combination of simplicity and efficiency results in a lower initial cost, less frequent repairs, and minimal energy costs, making centrifugal pumps a cost-effective solution for both small and large-scale applications.

6. Versatility in Applications

Centrifugal pumps are incredibly versatile and widely used across a range of industries that require the transfer of liquids.

Power Generation Industry

In power plants, centrifugal pumps play a vital role in circulating cooling water and transferring fuels, oils, and chemicals. Their reliability and energy efficiency make them an essential component in maintaining smooth plant operations.

Metallurgical Industry

In metallurgy, centrifugal pumps are used to handle various liquids, including molten metal, chemicals, and cooling agents. Their ability to manage high temperatures and corrosive substances makes them indispensable in this industry.

Coal and Mining Industry

Centrifugal pumps are widely employed in the coal and mining sectors for pumping slurry, water, and other liquids. Their ability to handle high flow rates with low maintenance requirements ensures that mining operations run smoothly and safely.

Building Materials and Construction

In the construction industry, centrifugal pumps are essential for transporting water, slurry, and concrete mixtures. Their ability to handle a variety of non-solid material fluids makes them highly effective in construction processes that require consistent fluid flow.

-

-

Multistage Pumps Factories play an essential role in modern industrial operations, producing pumps capable of handling high pressure and large volume applications. These factories focus on manufacturing multistage pumps ...

READ MORE -

Introduction to Jockey Pumps Jockey Pumps are integral components in fluid systems that require consistent pressure. Typically used in fire protection networks, they maintain pressure in pipelines when main pumps are ina...

READ MORE

浙公网安备33032402001888号

浙公网安备33032402001888号