It utilizes an nice domestic hydraulic model and adopts the performance parameters of the IS series centrifugal pump. The design is a clever combination based on a typical vertical pump, and it has been further derived into variations such as hot water, high-temperature, corrosive chemical pumps, and oil pumps based on different working conditions like temperature and media. This series offers advantages like high efficiency, energy saving, low noise, and reliable performance.

Product Features

The pump has a vertical structure, with both the inlet and outlet having the same diameter, located along the same centerline. It can be installed in pipelines like a valve, with a compact and aesthetically pleasing design. The pump occupies minimal space and has low construction investment. It can be used outdoors if equipped with a protective cover.

The impeller is directly mounted on the motor's extended shaft. The axial dimension is short, and the structure is compact. The pump and motor bearing configuration is rational, effectively balancing the radial and axial loads generated during operation, ensuring stable operation and minimal vibration and noise.

The shaft seal uses mechanical seals or a combination of mechanical seals, employing imported titanium alloy sealing rings, medium-temperature high-temperature mechanical seals, and hard alloy materials for wear-resistant sealing, which effectively extends the service life of the mechanical seals.

The pump is easy to install and maintain. There is no need to disassemble the pipeline system; all rotor components can be extracted by simply removing the pump's coupling nut.

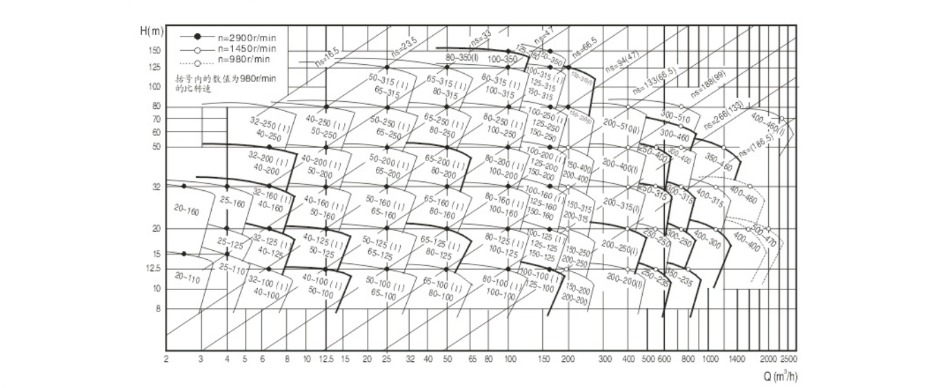

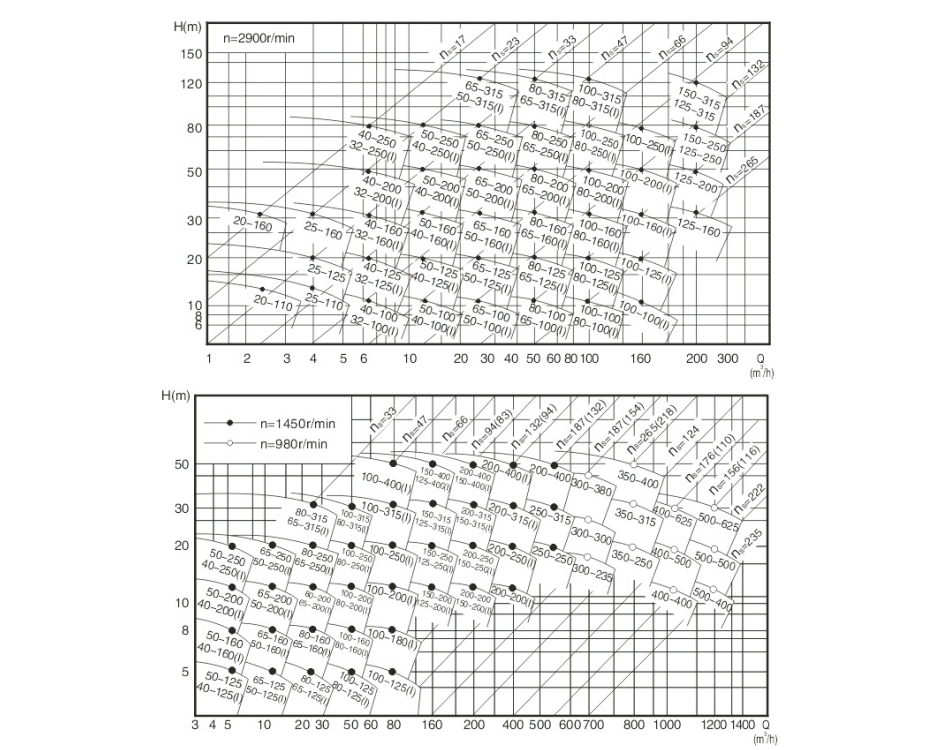

The pump can operate in series or parallel based on required flow and head.

The pump can be installed in both vertical and horizontal orientations according to the pipeline layout.

Main Applications

The ISG Single Stage Single Suction Vertical Pipeline Centrifugal Pump is used to transport clean water and other liquids with similar physical and chemical properties to water. It is suitable for industrial and urban water supply and drainage, booster water supply for high-rise buildings, garden irrigation, fire fighting, long-distance transportation, HVAC systems, bathroom cooling and heating water circulation, and equipment matching, with a working temperature T<80℃.

The IRG(GRG) series vertical hot water (high-temperature) circulation pump is widely used in: energy, metallurgy, chemicals, textiles, and papermaking, as well as in hotels, restaurants, and other boiler high-temperature water booster circulation systems, and urban heating systems. The IRG series operates at T<120℃, while the GRG series operates at T<240℃.

The IHG series vertical pipeline chemical pump is used for transporting liquids without solid particles that are corrosive and have viscosity similar to water. It is suitable for industries such as petroleum, chemicals, metallurgy, power, papermaking, food, pharmaceuticals, and synthetic fibers, with a working temperature range of -20℃ to 120℃.

The YG series vertical pipeline oil pump is used for transporting petroleum products such as gasoline, kerosene, and diesel, with the delivered medium's temperature range being -20℃ to 120℃.

Operating Conditions

The suction pressure should be ≤1.0 MPa or the maximum working pressure of the pump system should be ≤1.6 MPa, meaning the pump's suction pressure + pump head should be ≤1.6 MPa. The static pressure test of the pump is 2.5 MPa. Please specify the system working pressure when placing an order. If the working pressure exceeds 1.6 MPa, please request special arrangements at the time of order to ensure that the pump's flow and connection parts are made of cast steel during manufacturing.

The ambient temperature should be T<40℃, and the relative humidity should be <95%.

The solid particle volume content in the conveyed medium should not exceed 0.1% of the unit volume, with particle sizes greater than 0.2 mm.

Note: If the conveyed medium contains fine particles, please specify this when placing an order so the manufacturer can use wear-resistant mechanical seals.

浙公网安备33032402001888号

浙公网安备33032402001888号