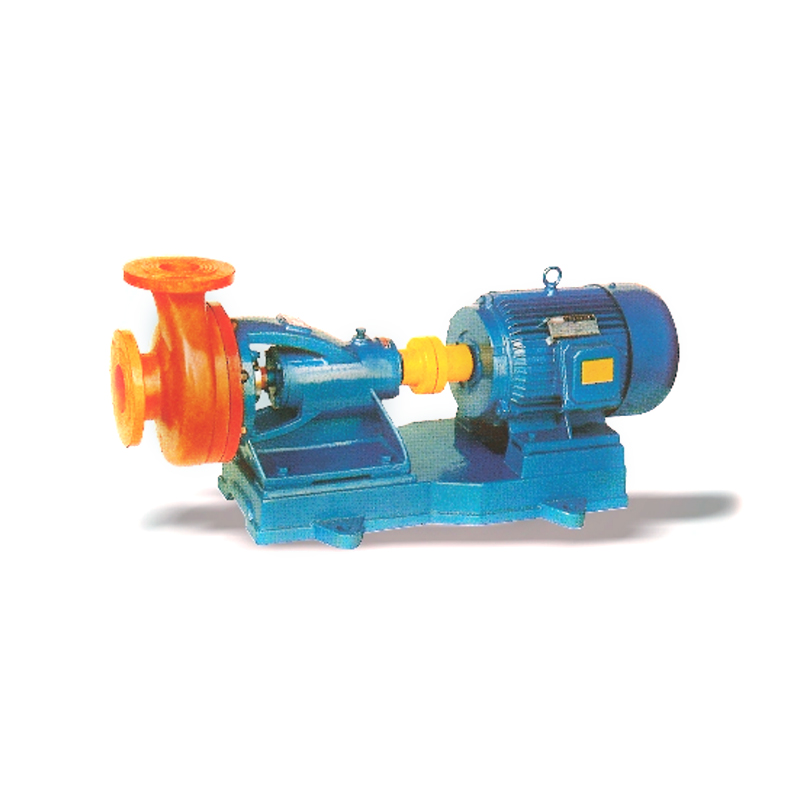

The pump offers nice properties such as light weight, high strength, no deformation, heat resistance, and corrosion resistance. In terms of corrosion resistance, it can partially replace precious metals like molybdenum-containing stainless steel, titanium, and titanium alloys.

Shaft Seal: The pump uses a WB2-type external mechanical seal with F4 corrugated seals, ensuring reliable sealing performance and long service life.

Pump Drive and Rotation Direction: The pump is directly driven by an electric motor through a claw-type flexible coupling. When viewed from the motor side, the pump rotates in a clockwise direction.

This pump is primarily used in industries such as petrochemical, metallurgy, dyes, textile printing and dyeing, pesticides, pharmaceuticals, rare earths, and fertilizers. It is ideal for transporting corrosive media such as non-oxidizing acids (e.g., hydrochloric acid, diluted sulfuric acid, formic acid, acetic acid, butyric acid), which do not contain solid particles, are not prone to crystallization, and have a temperature not exceeding 100°C.

Installation and Maintenance

Installation:

The FS type FRP centrifugal pump should be installed according to the selected pump model and its corresponding dimensions. Ensure that the installation location is accessible for management and maintenance, and that it is aligned with the pipeline requirements.

Liquid Filling Device:

If the pump body of the FS type FRP centrifugal pump is positioned higher than the liquid level, a liquid filling device must be installed.

Priming Before Start-Up:

Before starting the pump, it is essential to fill the pump body with liquid. It is strictly prohibited to run the pump or reverse the medium when the pump body is not filled, as this may damage the mechanical seal due to lack of liquid cooling.

Stopping the Pump:

When stopping the pump, close the liquid pipe valve to prevent liquid backflow.

Maintenance:

During maintenance, first remove the pump body, then loosen the mechanical seal screw and detach the mechanical seal.

Replacing Bearings or Pump Shaft:

If the ball bearing or pump shaft needs to be replaced, the frame must be removed. Loosen the 4 screws of the front bearing cover, unfasten the nut and coupling at the rear end of the pump shaft, and then move the front end of the pump. Finally, remove the rear axle cover.

Reassembly:

After replacing consumables or completing repairs, reassemble the pump.

浙公网安备33032402001888号

浙公网安备33032402001888号